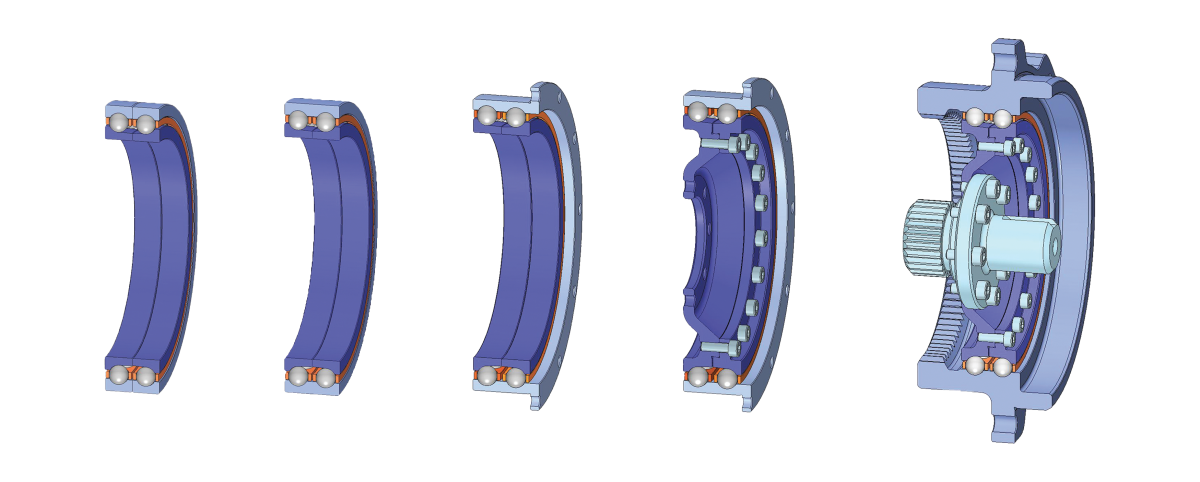

Integrated ball bearings

With its experience in high precision ball bearing technology, ADR has been able to develop unique skills in its integration.

Integrated ball bearings

The aim of this integration is to improve the capacity and behaviour of the rotating system by providing:

- – Increased rotation and guidance precision, repeatability (preloading and friction torque) and stiffness, depending on the chosen design;

- – Reduced dispersion and rejects.

Users can thereby optimise their production chain by avoiding any superfluous adjustment, setting and assembly time thanks to:

- – A reduction in the number of components, overall dimensions and mass;

- – Solid, adjusted and applied preloading;

- – Increased capacity and stiffness;

- – Reliable integration into the system and easy mounting.

This specific design uses materials and fluid lubricants or qualified solids and ensures the performance and repeatability of the behaviour of these bearings.

As assembly and final checks are performed in clean rooms, they provide a level of cleanliness and compatibility for some sectors where specific characteristics and technical mastery are mandatory, such as aerospace, defence & security, energy, medical or industry.

Sealed integrated bearings

To provide even more guarantees to its customers on the performance and reliability of its systems, ADR has developed a new bespoke technology in integrated seals for rotating systems.

The performance of established measurements, in terms of friction torque, stiffness and leakage rate, is systematically checked.

The integration of a dynamic seal on the ball bearing brings a controlled sealing function in terms of leak rate and repeatable low friction torque.